The advantages of tunnel freezers

High freezing speed: Tunnel freezers can quickly reduce the temperature of food in a short time, helping to maintain the quality and freshness of food. The rapid freezing process helps to reduce the size of ice crystals formed inside the food, thus minimizing damage to the cellular structure during thawing.

Energy efficiency: Modern tunnel freezers are designed with advanced insulation technology and efficient cooling systems, which provide optimal freezing effects while consuming less energy.

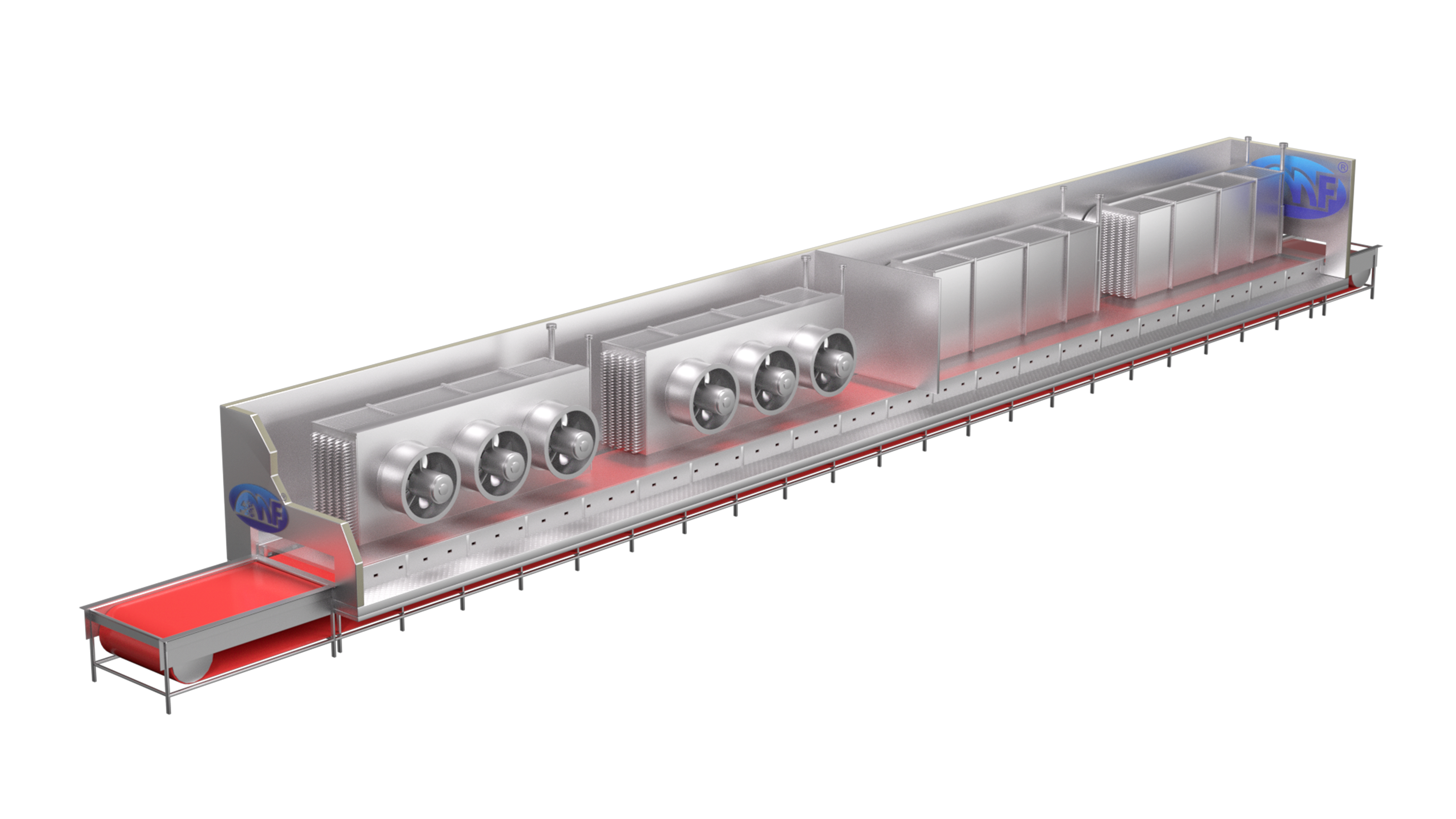

Continuous production capacity: Tunnel freezers are often designed to be part of a continuous production line, capable of processing large volumes of products without the need for downtime. This equipment is suitable for environments where large-scale processing is required, greatly improving production efficiency.

Uniform freezing: Due to the even distribution of cold air in the tunnel, all products passing through the freezer are uniformly frozen, ensuring consistent quality of each product.

Hygiene and safety: The design of tunnel freezers typically takes into account food safety and hygiene requirements, making them easy to clean and maintain, and helping to prevent food contamination.

Customizability: Depending on different production needs, tunnel freezers can be customized with different transport speeds, freezing times, and temperature settings, making them adaptable to various types of products and production processes.

These advantages make tunnel freezers an important tool in the food processing industry for maintaining product quality and improving production efficiency.

Post time: Jun-03-2024